Principles and Application Scope of Microchannel

Release Time:

2024-05-03

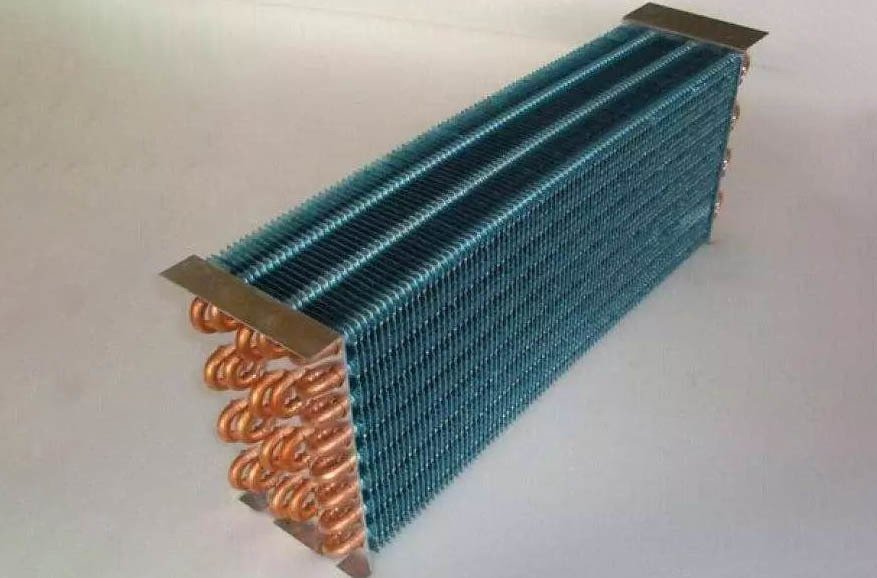

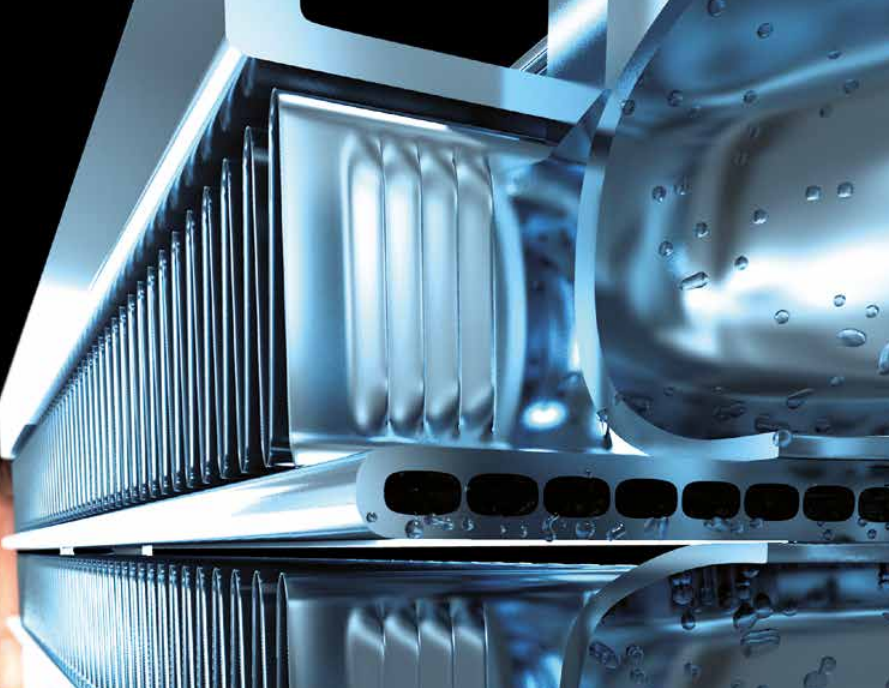

Microchannels, also known as microchannel heat exchangers, are heat exchangers with channel equivalent diameters ranging from 10-1000μm. These heat exchangers feature dozens of fine flow channels inside a flat tube, connected to circular manifolds at both ends of the flat tube. Baffles are installed within the manifolds to separate the heat exchanger channels into multiple processes. Compared to traditional chemical production, microchannels have significant potential for development and extensive application prospects in fine chemical engineering. So let's delve into microchannels from different aspects together.

I. Understanding Microchannel Reactors

Introduction to Microchannel Reactors

Essentially, a microchannel reactor is a type of continuous-flow tubular reactor. It includes mixers, heat exchangers, reactor controllers, and other chemical unit requirements. Currently, the overall structure of microchannel reactors can be divided into two types: one is an integral structure, which is manifested in the form of counterflow or countercurrent heat exchangers, enabling high-throughput operations in a unit volume. In an integral structure, only one operation step can be performed simultaneously, and these corresponding devices are ultimately connected to form a complex system. The other type is a layered structure, consisting of a stack of modules with different functions, where one operation is performed in one layer and another operation in another layer. Fluid flow in the various layer modules can be controlled by intelligent diversion devices to achieve higher throughput. Some microchannel reactors or systems are typically operated in parallel for greater throughput.

II. Principles of Microchannel Reactors

Microreactors mainly refer to small multi-channel reactors with channel sizes in the submicron and submillimeter range, manufactured using surface science and microfabrication technologies. The channel size of microreactors is only at the submicron and submillimeter levels. Microreactors have superior heat and mass transfer properties compared to traditional chemical equipment, making them particularly suitable for experiments with high heat release and fast reactions. Understanding the principles of microreactors is of interest to many.

The concept of microchemical technology originates from conventional-scale heat transfer mechanisms. For laminar flow inside a circular tube, when the wall temperature is constant, the heat transfer coefficient h is inversely proportional to the tube diameter d, as seen from formula (1). Similarly, for laminar flow inside a circular tube, when the concentration of component A at the tube wall remains constant, the mass transfer coefficient kc is inversely proportional to the tube diameter (formula (2)). Since flow inside microchannels mostly involves laminar flow, mainly relying on molecular diffusion to achieve fluid mixing, as shown in formula (3), the mixing time t is proportional to the square of the channel scale. Reducing the characteristic size of the channel not only significantly increases the specific surface area but also greatly enhances the transfer characteristics of the process.

Nu=hd/k=3.66(1)

Sh=kc/DAB=3.66(2)

t=d 2/DAB(3)

Here, Nu is the Nusselt number, Sh is the Sherwood number, and D is the diffusion coefficient. Chemical reactions conducted in chemical processes are controlled by the transfer rate or intrinsic reaction kinetics or both. For instantaneous and rapid reactions, when conducted in traditional-scale reaction equipment, they are controlled by the transfer rate. In microscale reaction systems, due to the significant increase in the transfer rate, the reaction rates of such processes will be greatly enhanced.

As for slow reactions, which are mainly controlled by intrinsic reaction kinetics, one of the key means to intensify the process is to increase the intrinsic reaction rate, usually achieved by increasing the reaction temperature or changing the process operating conditions.

At present, most industrial applications of hydrocarbon nitration reactions belong to the category of medium-slow reaction processes, with reaction times ranging from tens of minutes to hours. In microreactors, adiabatic nitration can be used, and changing the process conditions simultaneously can shorten the reaction time to seconds. Thus, theoretically, almost all reaction processes can be intensified.

More News

2024/05/09

Enhancing Heat Transfer in Finned Heat Exchangers

Finned heat exchangers are widely utilized in various applications, characterized by the addition of fins to traditional heat exchange tubes. These fins significantly increase the surface area for contact with external fluids, thereby improving heat transfer efficiency.

2024/05/03

Principles and Application Scope of Microchannel

Microchannels, also known as microchannel heat exchangers, are heat exchangers with channel equivalent diameters ranging from 10-1000μm. These heat exchangers feature dozens of fine flow channels inside a flat tube, connected to circular manifolds at both ends of the flat tube.

2024/04/26

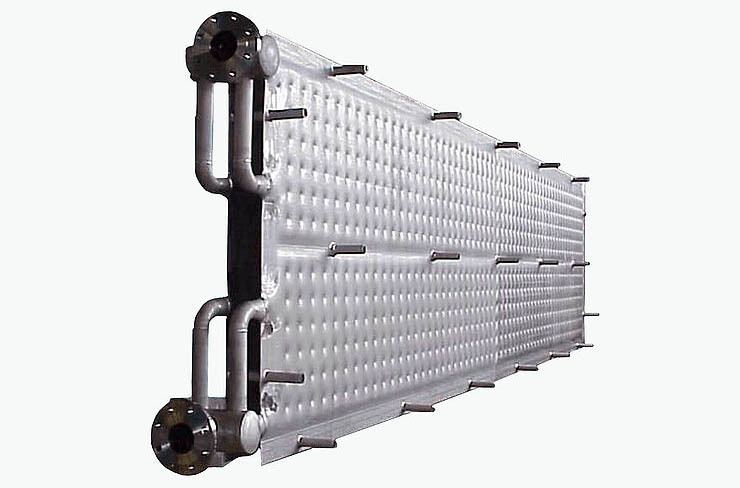

Exploring Pillow Plate Technology

Pillow plates represent a captivating advancement in engineering, crafted through an innovative inflation process. This technique involves seamlessly welding together two sheets of stainless steel or mild steel using sophisticated laser or resistance welding methods.