Enhancing Heat Transfer in Finned Heat Exchangers

Release Time:

2024-05-09

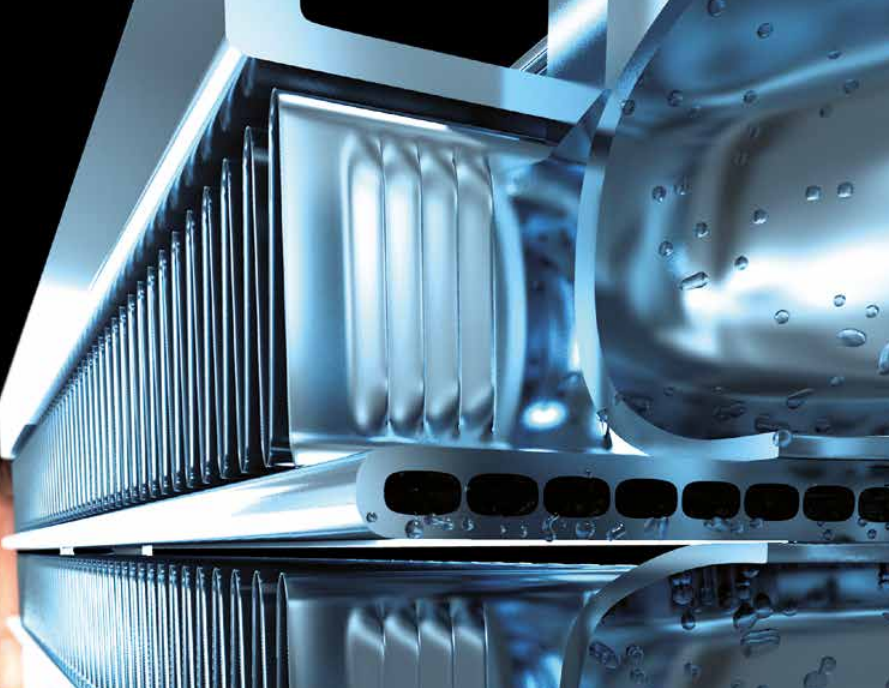

1. Introduction to Finned Heat Exchangers

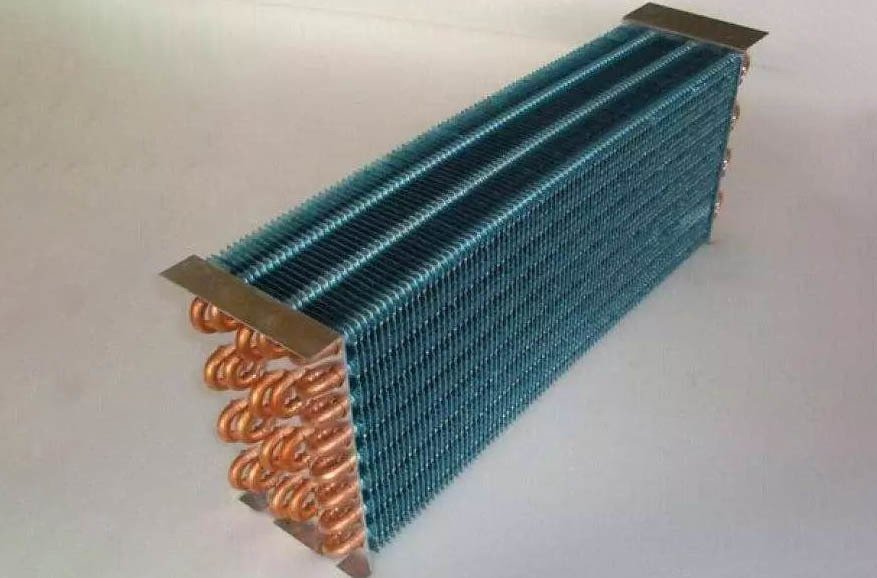

Finned heat exchangers are widely utilized in various applications, characterized by the addition of fins to traditional heat exchange tubes. These fins significantly increase the surface area for contact with external fluids, thereby improving heat transfer efficiency. The core component of a finned heat exchanger is the finned tube, where external fins augment the contact area with external fluids to achieve higher heat transfer efficiency.

2. Basic Structure of Finned Heat Exchangers

Finned heat exchangers primarily consist of:

Fins: Typically made of aluminum or other high thermal conductivity materials to increase the heat exchange surface area.

Tubes: The main channels through which fluids flow, available in circular, elliptical, or flat shapes.

Manifolds: Used for distributing and collecting fluids, ensuring uniform distribution across the tubes.

Types of Heat Exchangers: Currently, common heat exchangers in the refrigeration equipment industry include finned, microchannel, serpentine, blown, and shell-and-tube heat exchangers.

3. Advantages and Disadvantages of Finned Heat Exchangers

Advantages:

High heat transfer efficiency: Increased surface area due to fins enhances heat transfer efficiency significantly.

Flexible design: Different shapes and sizes of fins and tubes can be chosen as per requirements.

Space-saving: Finned heat exchangers are typically smaller and lighter than other types, thanks to their efficient heat transfer performance.

Disadvantages:

High manufacturing cost: Additional materials and processing techniques contribute to higher manufacturing costs.

Difficult cleaning and maintenance: Accumulation of dust and impurities between fins and tubes may occur, requiring regular cleaning.

4. Technological Origin and Development of Finned Heat Exchangers

The origins of finned heat exchangers can be traced back to the early 20th century, primarily for industrial applications such as automotive cooling and industrial cooling. With technological advancements, they gradually found application in more fields like residential air conditioning, refrigeration, and freezing equipment.

Compared to other types of heat exchangers, finned and microchannel heat exchangers offer better heat transfer performance and relatively smaller sizes for the same cooling capacity. However, microchannel heat exchangers face limitations due to their susceptibility to dust accumulation and frosting. Overall, finned heat exchangers exhibit excellent heat transfer performance and reliability, with broader applicability and adaptability to the overall direction of heat exchanger development.

New Technologies and Structural Designs

With continuous technological progress, the structural design of finned heat exchangers is innovating. For instance, traditional straight fins are gradually being replaced by curved or corrugated fins, improving heat transfer efficiency and reducing air resistance for enhanced overall energy efficiency. Additionally, new fin materials such as nano-coated fins and superhydrophobic fins further enhance heat transfer efficiency while mitigating frost and condensation issues.

Improvement Designs

To meet the growing demands for energy efficiency and environmental protection, design schemes for finned heat exchangers are continuously improving. Optimization of fin shapes and arrangements can further boost heat transfer efficiency. Utilizing new refrigerants and lubricants can reduce environmental pollution, while modular designs for heat exchangers simplify installation and maintenance processes. Furthermore, advanced control technologies like variable frequency control and intelligent control enhance the operational efficiency and reliability of finned heat exchangers.

Conclusion

Finned heat exchangers represent efficient and versatile heat transfer equipment extensively used in various industrial and commercial systems. With ongoing technological advancements, the performance and application range of finned heat exchangers are expanding, providing efficient and reliable heat transfer solutions for various applications.

Previous

More News

2024/05/09

Enhancing Heat Transfer in Finned Heat Exchangers

Finned heat exchangers are widely utilized in various applications, characterized by the addition of fins to traditional heat exchange tubes. These fins significantly increase the surface area for contact with external fluids, thereby improving heat transfer efficiency.

2024/05/03

Principles and Application Scope of Microchannel

Microchannels, also known as microchannel heat exchangers, are heat exchangers with channel equivalent diameters ranging from 10-1000μm. These heat exchangers feature dozens of fine flow channels inside a flat tube, connected to circular manifolds at both ends of the flat tube.

2024/04/26

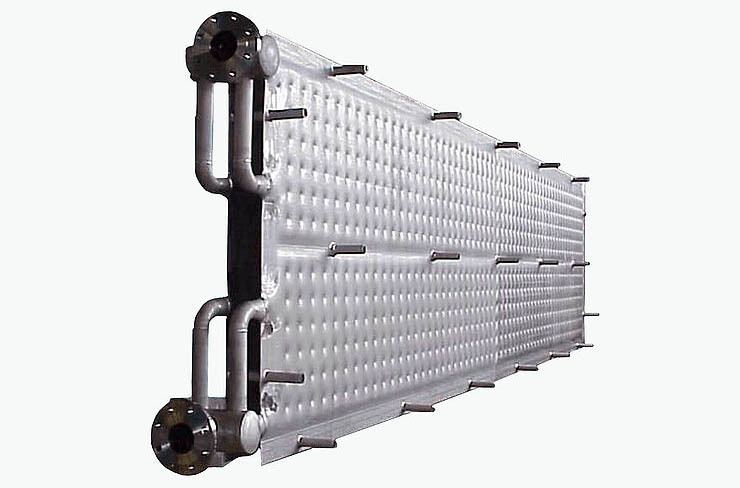

Exploring Pillow Plate Technology

Pillow plates represent a captivating advancement in engineering, crafted through an innovative inflation process. This technique involves seamlessly welding together two sheets of stainless steel or mild steel using sophisticated laser or resistance welding methods.