Project Case

Customized Deep Drawn & Welding Product

Overview:

In this success story, we will explore a case where a customer approached a metal fabrication company in need of a customized pipe fitting. Our company utilized deep drawing & welding processing techniques to meet customer’s requirements. Through close collaboration, designing, and adjustments to the 3D drawings, the company successfully delivered a solution that exceeded the customer's expectations.

Situation:

A customer from Japan hopes to get customized pipe fittings to match his products. He didn't have exact drawings, just a product picture and size information. The customer has high requirements on the size and surface treatment of fittings. He required a custom-designed component that could align perfectly with his assembly product.

Solution:

1.Communication about requirements

Our customer showed the product pictures to us, and we confirm the relevant information of the product with our customer, including the product size, the required quantity, the material requirements, the production process and the surface treatment.

In terms of the requirement of our customer, we provided a suitable quotation, and he was willing to accept it, then we started production process.

2. Design and Adjustments:

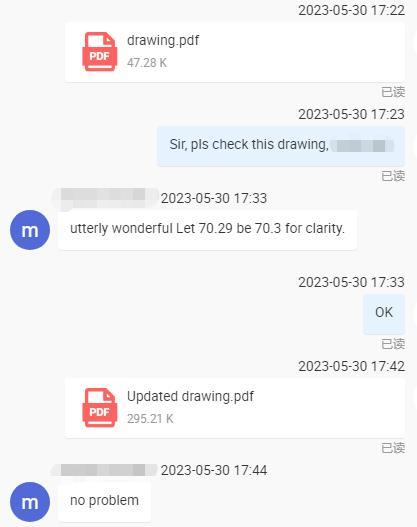

Using the information gathered during discussions and inspections, our team created a preliminary 3D design of the product. We presented it to our customer, then he provided feedback and requested certain adjustments. Through various iterations and design modifications, our technical engineer finally completed the drawing design.

3. Deep Drawing Processing:

After final design was approved, we utilized deep drawing and welding processing techniques to this product. Deep drawing is an effective method that maintains superior metal strength while achieving complex designs and tight tolerances. Then the two parts of the product are welded using carbon dioxide arc welding.

4. Quality Assurance:

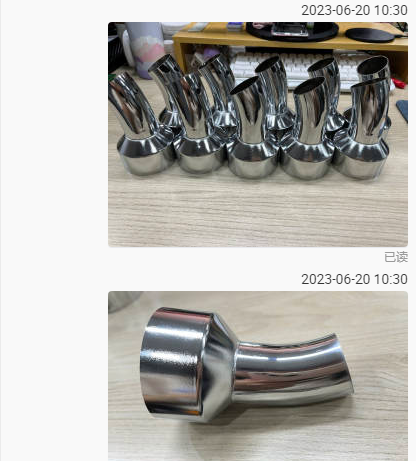

We first made 10 samples, then took photos and sent them to the customer to confirm the samples.

Throughout the fabrication process, we adhered to rigorous quality control measures to guarantee the highest standards. The customer was very satisfied after receiving the samples, which also exceeded his expectations. And finally, our customer confirmed the bulk order of this product.

Customer's Positive Feedback:

Our customer is satisfied with the product sample, and said amazing!