How to ensure your customized product get succeed

Massive manufacturing partner network

◆ We have 3 invested manufacturing factories that covers heat exchanger, sheet metal fabrication and CNC machining

◆ Over 10 top ranked factories in China are our regular manufacturers

◆ Over 100 manufacturers are providing us products or fabrication services

◆ Our manufacturing capabilities include a wide variety of process

★ Laser cutting

★ Bending

★ Welding

★ Stamping

★ Deep drawing

★ Metal spinning

★ CNC machining

★ Aluminum die casting

★ Aluminum extrusion

★ Vacuum brazing

★ CAB brazing

★ Surface treatment

★ Assembly and packing

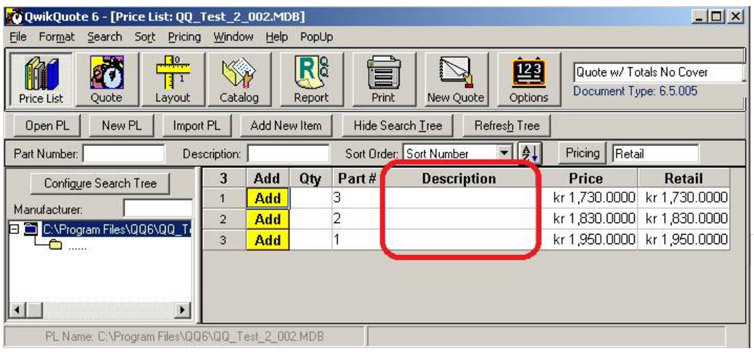

Instant quoting capability

◆ Our designed quoting program and software enable us to create one quotation in minutes

◆ Our computerized data base stores rich and massive technical parameters, engineering parameters, testing data and other available sources, which makes our engineers refine and calculate one offer much quicker and easier but accurately.

◆ Available software including CAD/CAM, UG, SOLIDWORKS help our work smarter

◆ Most important, our quoting team consists of cross-functional engineers. Our technical engineers, designing engineers, manufacturing engineers, quality engineers and sourcing engineers have year’s working experience in thermal industry. They work closely together to ensure your inquiry is clearly identified and one accurate and cost-effective offer is achieved

QUALITY ASSURANCE

◆ ISO9001, ISO14001, ROHS compliance certified

◆ TESTING AND INSPECTION

First article inspection

Incoming material inspection, and materials certified

In process quality inspection

Final quality inspection

Product liability testing

A series of testing and inspection are performed to control quality

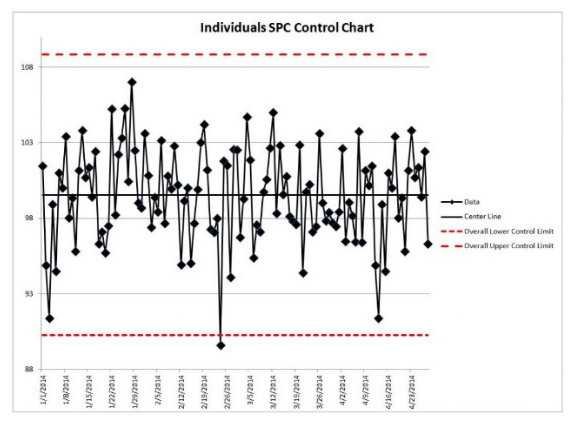

◆ SPC, Lean six sigma tools, process CPK analysis

Our engineering engineers perform regular CPK analysis for some key process to analyze and verify our process is stable and variable factors are under control

Our quality engineers follow up quality concept and use SPC, Lean six sigma tools to monitor quality status and further do continuous improvement

Our certified quality management system, combining effective testing and inspection operations, and process stability analysis, quality monitor and improvement ensure delivered goods meet quality standards.