Differences and Similarities between Vacuum Oil Quenching Furnace and Vacuum Gas Quenching Furnace

Release Time:

2024-09-20

Differences:

1. Applicable Materials

- Vacuum oil quenching furnaces are suitable for vacuum heat treatment of materials such as die steel, spring steel, stainless steel, bearing steel, and high-temperature alloy steel.

- Vacuum gas quenching furnaces are used for vacuum heat treatment of materials with good quenching permeability such as high-speed steel, stainless steel, and die steel.

2. Quenching Medium

- Vacuum oil quenching furnaces use liquid oil as the quenching medium, where the metal material is immersed in oil for cooling. They have lower operating costs, and the quenching oil can be reused.

- Vacuum gas quenching furnaces use gas as the quenching medium, cooling the material by introducing gas into the chamber. Gas cannot be reused.

3. Dual Chamber Structure

- Vacuum oil quenching furnaces can be designed with a dual-chamber structure, a feature not present in vacuum gas quenching furnaces.

Similarities:

1. Oxidation Avoidance

- Both types of equipment can conduct heat treatment in a vacuum environment, effectively preventing oxidation of the metal during heating, thereby enhancing the metal's purity and quality.

2. Energy Efficiency and Environmental Protection

- Both vacuum oil quenching furnaces and vacuum gas quenching furnaces can achieve efficient heating and cooling, reducing heat treatment time, lowering energy consumption, and minimizing environmental impact.

3. Improved Surface Quality

- Since materials are shielded from oxidation, the metal surface post heat treatment is smoother, aiding in subsequent processing and usage.

4. High Production Efficiency

- Both equipment types boast a high level of automation, enabling continuous production and improved efficiency.

Conclusion:

Vacuum dual-chamber oil quenching furnaces offer high performance, quality, and durability, suitable for quenching various metal materials. With proper maintenance and care, they can maintain excellent performance and stability over extended periods of use.

More News

2025/05/28

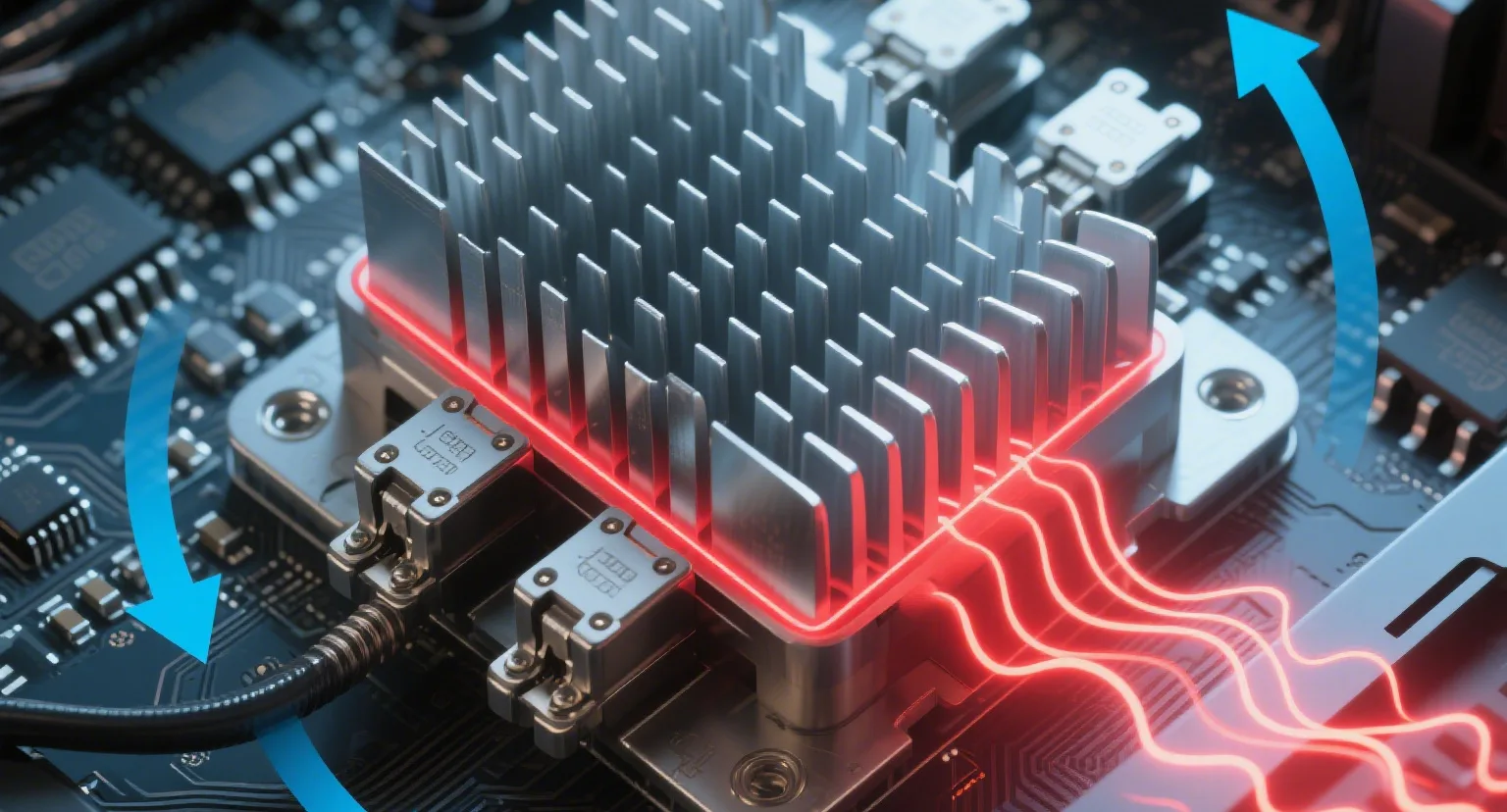

Heat Sinks in Power Electronics: Essential Components for Efficient Thermal Management

Discover how heat sinks enhance thermal management in power electronics for reliable, efficient performance.

2025/04/30

How Tube-Fin Heat Exchangers Revolutionize Industrial Chillers for Superior Cooling Solutions

Discover how tube-fin heat exchangers boost industrial chiller performance with enhanced cooling efficiency and reliability.

2025/03/24

Tube-Fin Heat Exchangers: A Key Technology for Efficient Heat Recovery Systems

Tube-fin heat exchangers enhance heat recovery with efficient transfer, compact design, and energy savings.