Dimple Plates vs Pillow Plates

Release Time:

2024-09-27

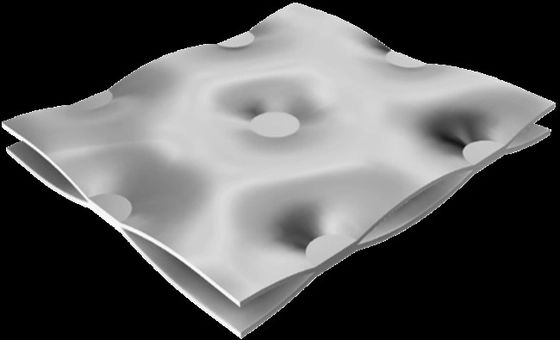

The term Dimple Plate is also often used for Pillow Plates. Originally, Dimple Plates are preformed sheets that are attached to the final product afterwards, while Pillow Plates are already being processed in the application. The use is largely the same, but in production time and usage possibilities, there are big differences.

Before Pillow Plates were produced with laser welding machines, pre-formed Dimple Plates were an alternative. With the arrival of laser welding machines the advantages and possibilities with Pillow Plates have grown enormously.

Difference in design

Both the pre-formed Dimple Plates and Pillow Plates can both be produced from stainless steel sheets. In the case of pre-formed dimple plates, dimples with a small hole are punched into the plate. After the plate has been rolled into the desired shape, the plate is welded to the end product. For example, existing tanks that have to be converted into a cooling tank.

Pillow Plates, on the other hand, are two plates that are welded together by a laser welding machine. After the plates are rolled in the right shape, the plate is only inflated and the Pillow Plate is evenly attached to the surface.

This offers many advantages over preformed Dimple Plates:

Welding with a machine is faster, so you save time

The laser welding machines are more accurate than manual work.

Application

The biggest difference between preformed Dimple Plate and Pillow Plates is in the application. Preformed Dimple Plates are suitable for small surfaces and mountend to the existing tank. In addition, pre-formed Dimple Plates can handle a maximum pressure of 4/5 bar, while Pillow Plates can be used at much higher pressures.

For segments where high pressure plays a major role, such as in the chemical or pharmaceutical industry, Pillow Plates are a good quality solution.

We are pleased to help you with a comparing heat transfer calculation!

More News

2025/07/30

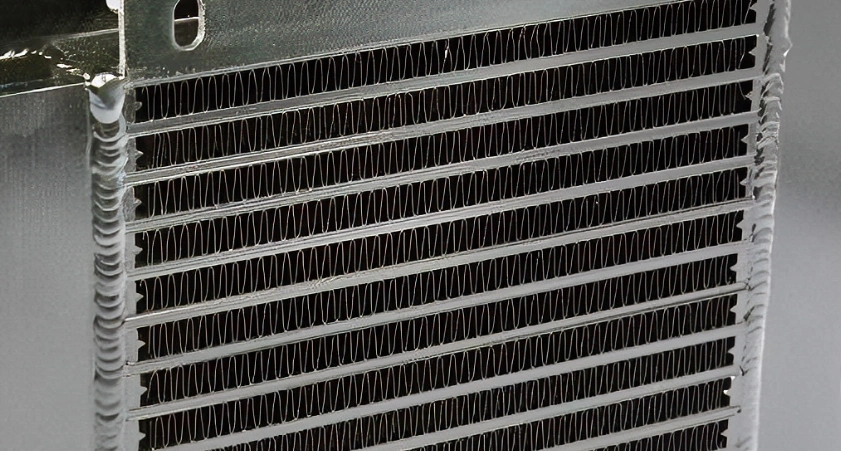

The Role of Plate-Fin Heat Exchangers in Optimizing Heat Transfer for Industrial Gas Systems

Discover how plate-fin heat exchangers improve heat transfer in industrial gas systems, offering high efficiency, compact design, and reliable thermal performance.

2025/06/27

Improving Heat Management in Oil And Gas Facilities with Plate-Fin Heat Exchangers

Learn how plate-fin heat exchangers improve heat management in oil and gas by boosting efficiency, saving space, and ensuring safe LNG processing.

2025/05/28

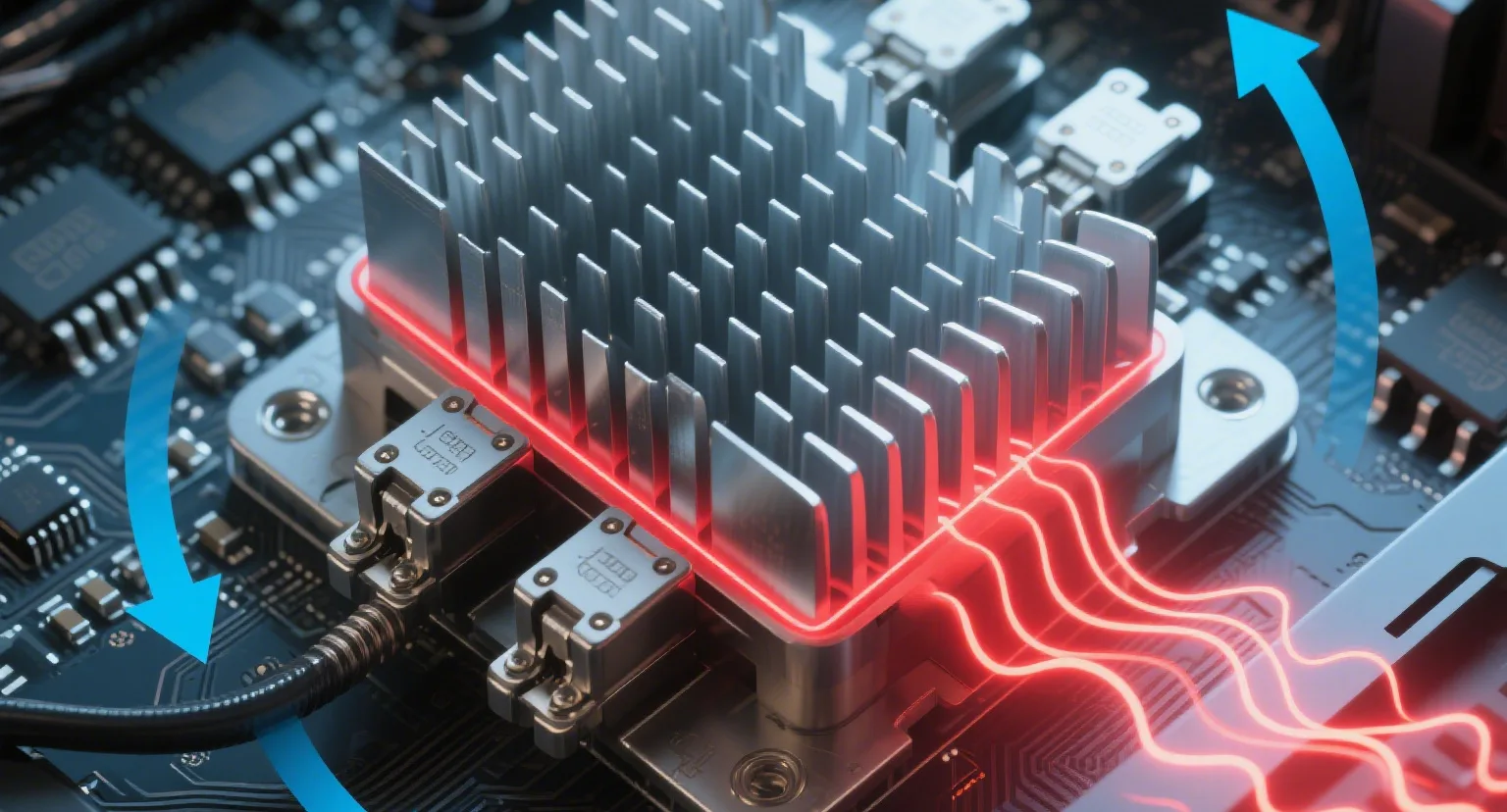

Heat Sinks in Power Electronics: Essential Components for Efficient Thermal Management

Discover how heat sinks enhance thermal management in power electronics for reliable, efficient performance.