Project Case

Maximizing Heat Transfer Efficiency in Chemical Processes: The Benefits of Plate-Fin Heat Exchangers

In the realm of chemical processing, effective heat management is paramount. Heat exchangers play a critical role in regulating temperature, ensuring that reactions occur under optimal conditions, and maintaining the safety and efficiency of industrial systems. Among the different types of heat exchangers used in the industry, plate-fin heat exchangers (PFHEs) stand out due to their high heat transfer efficiency, compact design, and versatility. These features make them particularly useful in chemical process cooling applications, where precise temperature control is essential for both product quality and energy savings.In this article, we will explore how plate-fin heat exchangers contribute to maximizing heat transfer efficiency in chemical processes, focusing on their advantages, design considerations, and specific benefits within the context of chemical process cooling.

Understanding Plate-Fin Heat Exchangers

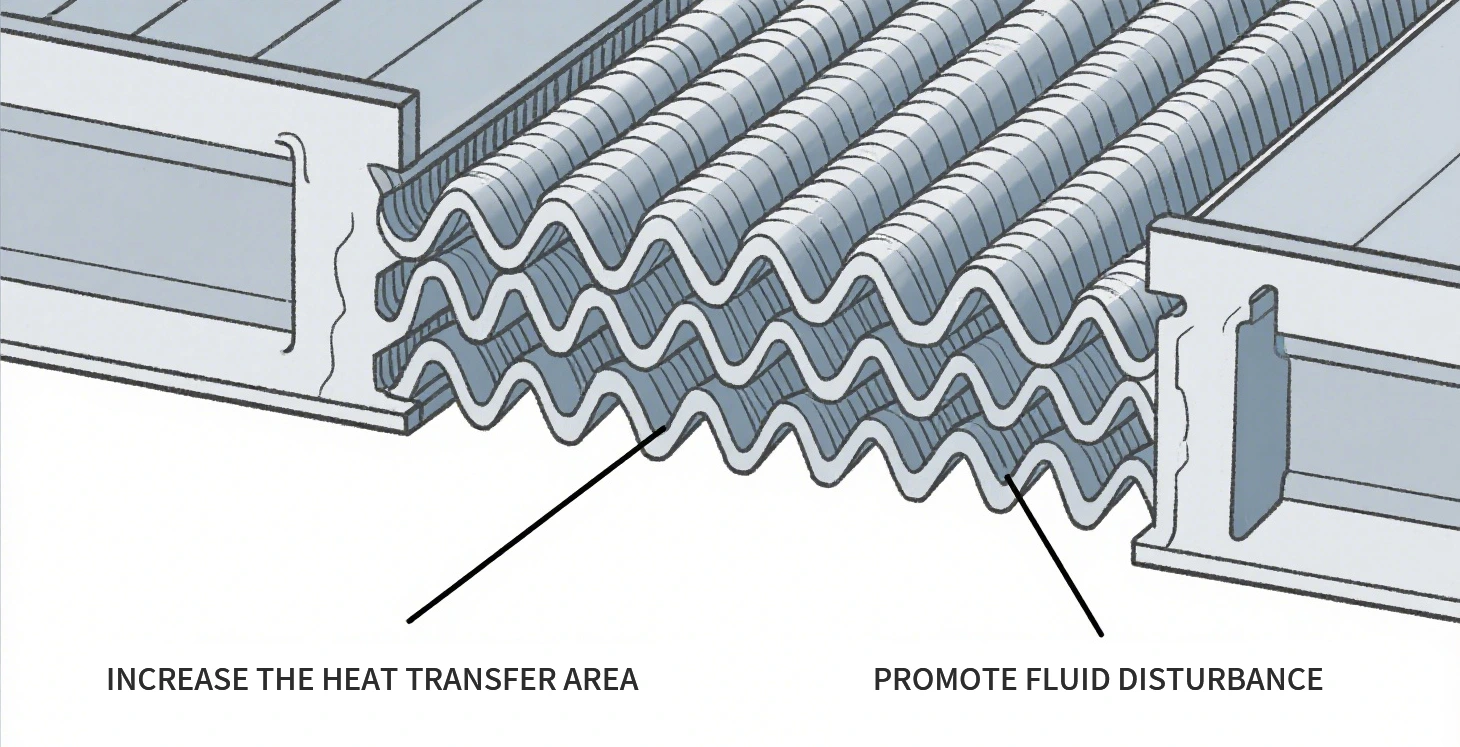

A plate-fin heat exchanger consists of multiple corrugated plates arranged in a stacked configuration, with thin metal fins placed between the plates. The fins create additional surface area, enhancing the heat transfer process. This design provides a significant advantage over traditional heat exchangers, which may rely solely on the surface area of the plates for heat transfer. The plate-fin construction allows for greater efficiency in heat exchange by offering increased surface area and turbulence, which helps to enhance heat transfer rates.

Plate-fin heat exchangers are widely used in a variety of applications, including chemical processing, aircraft cooling systems, HVAC systems, and cryogenic applications. Their compact design and high thermal performance make them ideal for situations where space is limited or high thermal performance is required, both of which are common in chemical processing environments.

The Role of Plate-Fin Heat Exchangers in Chemical Process Cooling

Chemical processes often generate substantial amounts of heat during reactions, especially in industries such as petrochemicals, pharmaceuticals, and food production. In these processes, maintaining precise temperature control is essential to ensure that chemical reactions occur efficiently and safely.

Here’s how plate-fin heat exchangers help in chemical process cooling:

1. Efficient Heat Transfer in Small Spaces

Chemical processes frequently involve high temperatures, and controlling these temperatures within narrow limits is necessary for the efficiency and safety of the system. Plate-fin heat exchangers provide superior heat transfer in a compact form factor, which is essential when dealing with limited space, such as in modular chemical plants or highly packed industrial environments.

The compact design of PFHEs allows them to fit into tight spaces without compromising on heat transfer performance. Their structure enables them to effectively cool the process fluid, which can be crucial in preventing overheating or in maintaining specific temperature gradients for optimal chemical reactions.

2. Increased Heat Transfer Efficiency

One of the main advantages of plate-fin heat exchangers is their ability to maximize heat transfer. This is achieved due to the increased surface area provided by the corrugated plates and fins. The turbulence induced by the fins ensures that the fluid flow is disrupted, creating more contact between the fluid and the surface, which accelerates heat transfer.

In chemical process cooling, where precise temperature regulation is essential, the ability to transfer heat efficiently helps maintain the temperature within optimal ranges, preventing overheating, which can cause degradation of products or hazardous situations. The ability to extract heat efficiently also reduces energy consumption by minimizing the need for additional cooling equipment.

3. Enhanced Durability and Reliability

Plate-fin heat exchangers are typically constructed from durable materials such as stainless steel, aluminum, or titanium, all of which are highly resistant to corrosion, wear, and thermal stresses. This robustness ensures that PFHEs can operate effectively even in harsh chemical environments, where the process fluids may be corrosive or the temperatures extremely high.

In chemical processes, reliability is critical. Over time, many heat exchangers may suffer from fouling or corrosion, which can reduce efficiency and lead to costly downtime. The durability of plate-fin heat exchangers ensures longer operational lifespans and more consistent performance, making them a cost-effective choice in the long run.

4. Flexibility for Different Fluids and Operating Conditions

Another key benefit of plate-fin heat exchangers in chemical process cooling is their versatility. These heat exchangers can handle a wide variety of fluids, including corrosive chemicals, hot gases, and steam, making them suitable for diverse chemical processes. Their modular design allows for customization, with adjustable flow paths and configurations tailored to specific application needs.

In industries like petrochemical manufacturing, pharmaceuticals, and food processing, process fluids can vary widely in terms of temperature, viscosity, and chemical properties. Plate-fin heat exchangers can be designed to meet these unique requirements, ensuring effective cooling in a range of operating conditions.

Design Features of Plate-Fin Heat Exchangers for Chemical Processes

When it comes to optimizing plate-fin heat exchangers for chemical process cooling, several design factors play an important role in maximizing performance:

1. Finned Surface Area

The primary reason for the superior heat transfer capabilities of plate-fin heat exchangers is the large surface area provided by the plates and fins. By increasing the number and size of the fins, manufacturers can create more surfaces for heat to be exchanged, which improves the overall efficiency of the heat exchanger.

Finned surfaces also allow for improved heat dissipation, ensuring that heat is quickly removed from the process fluids and transferred to a cooling medium, such as water or air.

2. Material Selection

In chemical process cooling, the fluids used can be highly corrosive or contain particulates that may affect heat transfer surfaces. As a result, material selection is a critical factor in the design of plate-fin heat exchangers. Stainless steel, aluminum, and titanium are commonly used materials due to their corrosion resistance, strength, and ability to withstand extreme temperatures.

Manufacturers of plate-fin heat exchangers can customize the materials to match the specific chemical and thermal conditions of the process, ensuring that the heat exchanger operates at optimal efficiency without corrosion or degradation over time.

3. Configuration and Flow Path Design

The configuration and flow path of a plate-fin heat exchanger are essential to maximizing heat transfer efficiency. There are different flow configurations, such as counterflow, parallel flow, and crossflow, each of which has different advantages depending on the specific application.

In chemical process cooling, counterflow heat exchangers are particularly effective, as they allow the process fluid and cooling fluid to flow in opposite directions, which leads to more efficient heat transfer. The flow path design also impacts how the fluids interact with the fins, helping to optimize the turbulence and contact surface area for better heat exchange.

4. Integrated Filtration and Cleaning Mechanisms

To maintain long-term efficiency, plate-fin heat exchangers may incorporate integrated filtration and cleaning systems. Over time, fouling from impurities in the process fluids can reduce heat transfer performance. Cleaning mechanisms, such as backflushing or chemical cleaning, can help maintain the heat exchanger’s performance by removing any buildup that may occur.

Some advanced PFHE designs also feature self-cleaning or automatic cleaning technologies, which are particularly useful in industries with high fouling potential, such as food processing or petrochemical manufacturing.

Conclusion

Plate-fin heat exchangers are highly efficient tools for chemical process cooling, offering excellent heat transfer, compact design, versatility, and durability. These features make them ideal for applications in petrochemical plants, pharmaceutical manufacturing, and food production, ensuring precise temperature control, optimized chemical reactions, and improved safety and efficiency. NANJING METALLI INDUSTRIAL CO., a leader in heat exchange technologies, provides high-quality plate-fin heat exchangers tailored to meet the needs of chemical processes.

As industries focus on performance, energy savings, and safety, plate-fin heat exchangers will play an increasingly crucial role in chemical process cooling. Their compact, durable design makes them essential in modern chemical processing systems, helping companies meet operational and environmental goals. NANJING METALLI INDUSTRIAL CO., with its commitment to innovation, ensures that chemical manufacturers have access to reliable, high-performance heat exchange solutions.