PRODUCTS

A plate-fin heat exchanger uses "sandwiched" passages with fins to increase the unit's effectiveness. The designs include crossflow and counterflow configurations, coupled with various fin configurations, including straight, offset, and wavy fins.

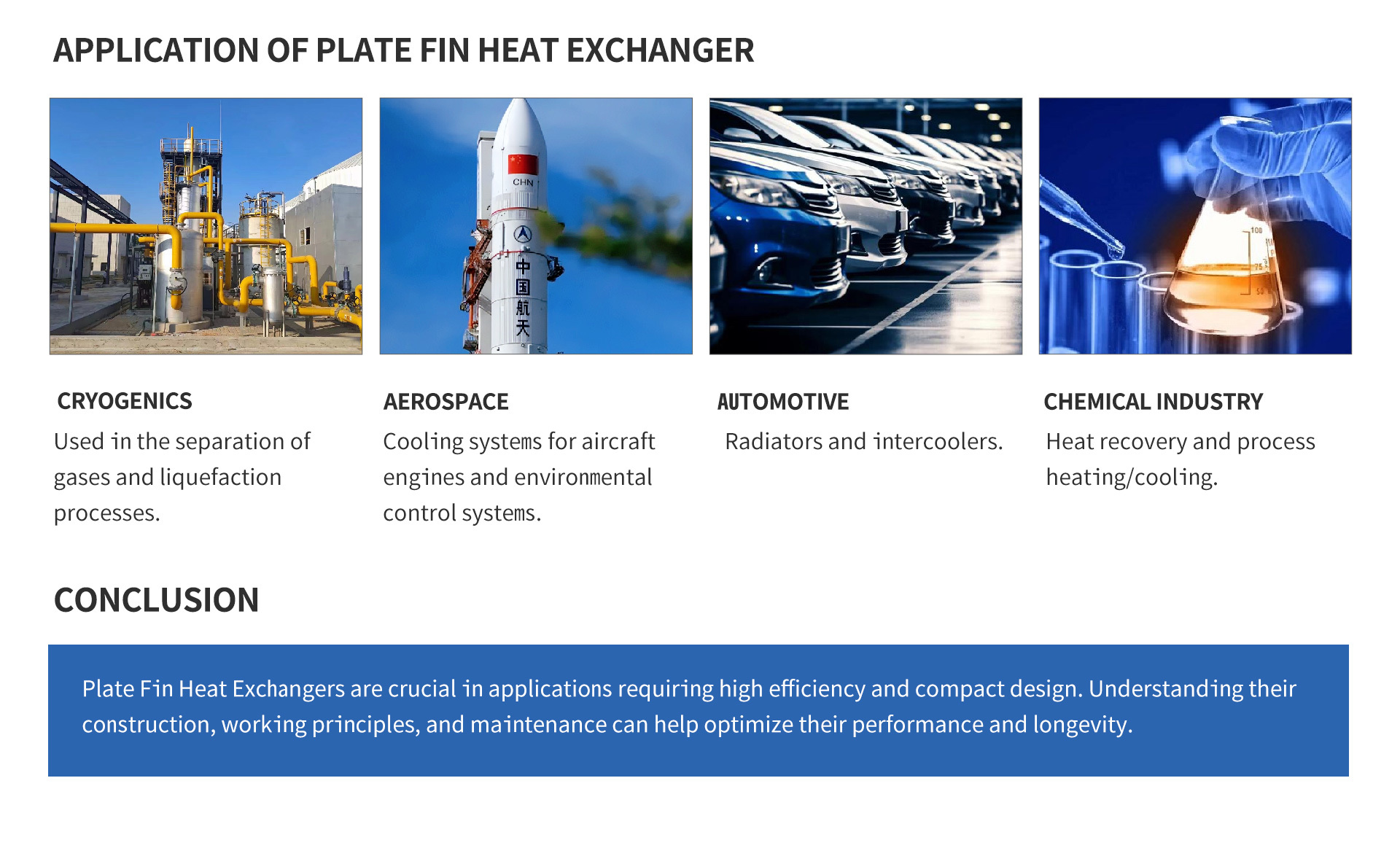

Plate-and-fin heat exchangers are usually made of aluminum alloys, which provide high heat transfer efficiency. The material enables the system to operate at a lower temperature difference, reducing the equipment's weight. Plate and fin heat exchangers are primarily used for low-temperature services, such as natural gas, helium, and oxygen liquefaction plants, air separation plants, and transport industries, such as motor and aircraft engines.

Benefits of Metalli's plate and fin heat exchangers:

• High heat transfer efficiency, especially in gas treatment

• Larger heat transfer area

• Approximately 5 times lighter in weight than that of a shell and tube heat exchanger.

• Able to withstand high pressure

A Plate Fin Heat Exchanger (PFHE) is a type of compact heat exchanger used in various industries for its high efficiency and compact size. It is constructed from thin plates and fins, providing a large surface area in a small volume and enhancing heat transfer.

CONSTRUCTION AND DESIGN

Plates: Thin metal plates form the primary structure, creating separate channels for different fluids.

Fins: Attached to the plates, fins increase the surface area for heat transfer.

Core: The assembly of plates and fins forms the core of the heat exchanger.

Manifolds: These are used to distribute and collect fluids at the inlet and outlet.

WORKING PRINCIPLE

Fluid Flow: Hot and cold fluids flow through alternate channels created by the plates.

Heat Transfer: Heat is transferred from the hot fluid to the cold fluid through the thin plates, with the fins enhancing the transfer.

Thermal Efficiency: The fins' large surface area increases heat transfer efficiency.

ADVANTAGES OF PLATE FIN HEAT EXCHANGER

HIGH EFFICIENCY

Due to the large surface area relative to volume.

COMPACT SIZE

Takes up less space compared to shell-and-tube heat exchangers.

VERSATILITY

It can handle different fluids and a wide range of temperatures and pressures.

SCALABILITY

Easy to scale up or down based on the application.