PRODUCTS

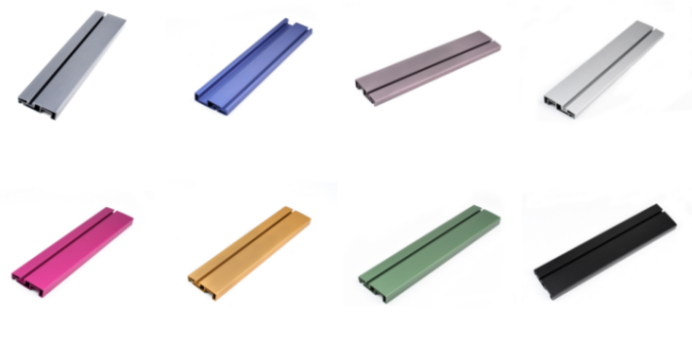

High Quality OEM Aluminum Extruded Profile with Anodizing Surface

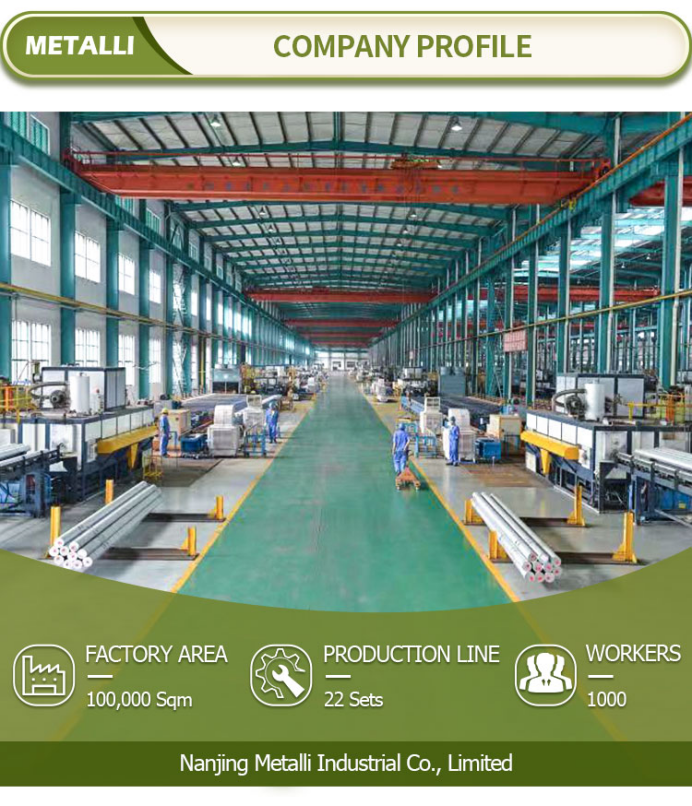

We have been providing thermal solutions over 15 years for almost every industrial application field covering electronics, power generations, data centers, new energy, automobile, medical, chemical and construction machinery.

Category:

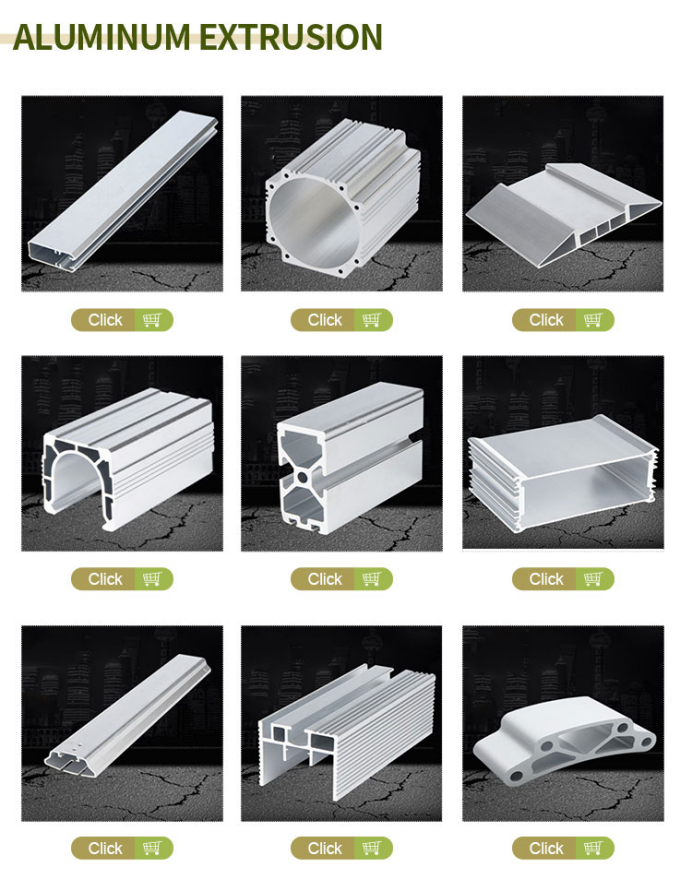

Custom Aluminum Profile

Aluminum Extrusion

Enter product details or other specific requirements to receive an accurate quote. We will reply within 24 hours.

|

Place of Origin |

Jiangsu, China |

|

Delivery Time |

15-21 days |

|

Temper |

T3-T8 |

|

Application |

Custom |

|

Shape |

Custom |

|

Alloy Or Not |

Is Alloy |

|

Model Number |

NM-AEP0001 |

|

Brand Name |

Nanjing Metalli |

|

Processing Service |

Bending, Decoiling, Welding, Punching, Cutting |

|

Product name |

Aluminum extrusion service construction Oem aluminum profiles |

|

Material |

AA6000 series |

|

Temper |

T3,T4,T5,T6 |

|

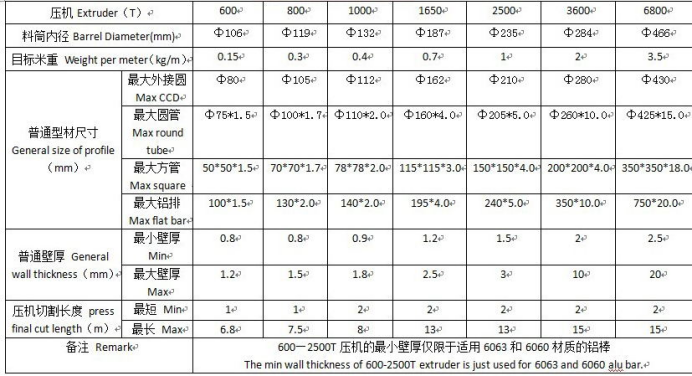

Length |

Up to 6000mm |

|

Width |

Up to 500mm |

|

Height |

Up to 500mm |

|

Wall thickness |

At least 1mm |

|

Standard |

GBT6892-2000 |

|

Surface finish |

Powder coating,oxidation,etc. |

|

Certificates |

CE,CCC,RoHS |

We are expert in metal fabrication and have been providing solution almost every industrial application imaginable over 10 years, specializing in designing and manufacturing metal fabrication parts. From 2014, we are under the name of Nanjing metalli Industrial Co.,Ltd.

Metalli's metal fabrication capabilities includes below:

1.Sheet metal fabrication including stamping, deep drawing,bending, metal spinning;

2.Welding 3.Aluminum Extrusion

4.Aluminum Die Casting

5.CNC Machining 6.Other custom metal fabrication solutions

Our capabilities cover a wide range that provide you one-stop solution quicker and easier. Our main capabilities include:

1. Vacuum Brazing and Controlled Atmosphere Brazing

2. CNC machining

3. Welding

4. Aluminum extrusion

5. Aluminum die casting

6. Sheet metal fabrication covering laser cutting, stamping, drawing and bending

7. Surface coating

We emphasis prototype process. we use our vast experience in fluid dynamics, thermal performance, and material compatibility to optimize your design. To perform advanced thermal analysis, our engineers use simulation software like CFD, 6 Sigma. In addition to providing expert thermal and mechanical design engineering, we ensure that your products fit DFM concept so that your products can be built to your exact specifications as well as meet your delivery schedule.

We see quality aspects from manufacturing viewpoints. Focusing more on monitoring and minimizing process variable to keep stable quality level. Delivered products are performed 100% inspection or testing. Less worries of quality risk and loss.

Our lean manufacturing and continuous improvement program aim at eliminating all wastes that do not add values. Our customers do not need to pay for wastes. The cost will be more and more competitive that help grow up your business and build your success.

key word: