PRODUCTS

What Is a Pillow Plate Heat Exchanger?

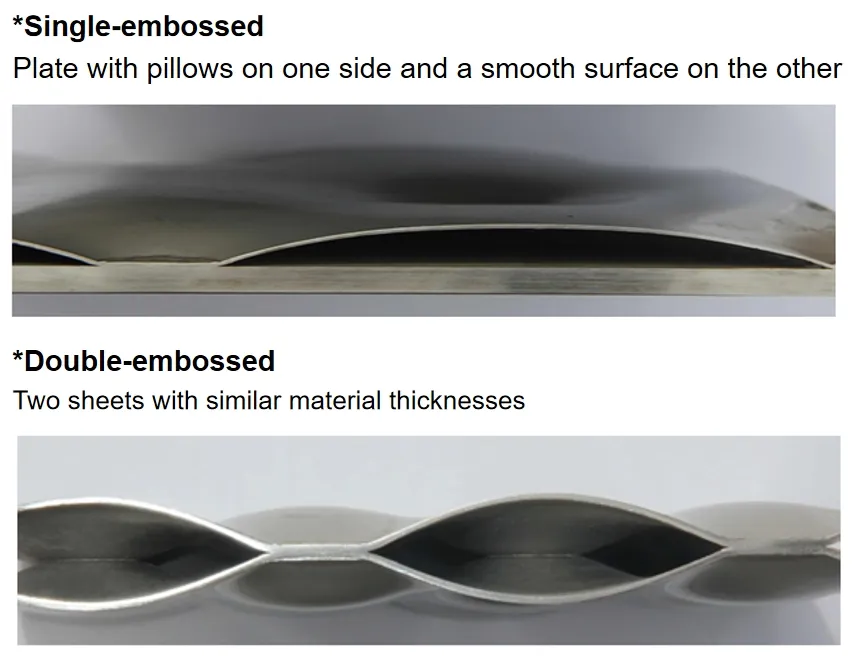

A pillow plate is a type of heat exchanger component made from two stainless steel sheets laser-welded in a custom circular pattern. After welding, the plates are inflated using high pressure, creating an internal cavity that allows efficient flow of heat transfer media such as liquids, steam, or refrigerants.

Beyond the internal flow channel, the space between adjacent pillow plates—known as the external, or outer, channel—also supports fluid flow. This dual-channel structure enables efficient heat transfer between the internal and external media, promoting even temperature distribution throughout the system.

Thanks to its compact structure and high thermal efficiency, the pillow plate is widely used in industrial cooling, heating, and energy recovery systems.

Product Features of Pillow Plate Heat Exchanger

Innovative Pillow Plate Design

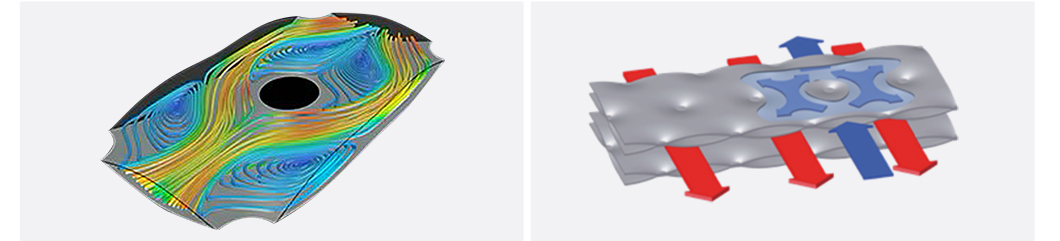

The custom-inflated pillow structure creates a larger surface area for thermal exchange, enabling high-efficiency heat transfer between the fluid and the plate.

High Mechanical Strength & Corrosion Resistance

Constructed from premium stainless steel, the plate offers excellent durability and corrosion resistance, making it ideal for demanding industrial environments.

Wave-Surface Flow Optimization

The wave-like internal surface design promotes turbulent flow, boosting heat transfer performance and reducing the risk of fouling.

Space-Efficient Compact Structure

Its compact and lightweight construction simplifies integration into existing systems while saving valuable installation space.

Consistent and Uniform Heat Distribution

The dual-channel flow design ensures even temperature control, improving system stability and operational precision.

Product Advantages of Pillow Plate Heat Exchanger

Exceptional Heat Transfer Efficiency

The laser-welded pillow plate design creates turbulent internal flow, significantly increasing the overall heat transfer coefficient.

Energy-Efficient Operation

Its compact internal volume minimizes the amount of cooling or heating fluid required, reducing pump load and overall energy consumption.

Low Maintenance Requirements

High turbulence flow prevents the buildup of deposits such as lime scale and algae, extending service intervals and reducing maintenance costs.

Cost-Effective Design

The pillow plate structure supports the use of thinner materials and streamlined welding, lowering production costs without compromising performance.

Low-pressure Drop

Engineered for smooth and efficient fluid circulation, the design minimizes resistance while maintaining optimal flow rates.

Stable Process Performance

Uniform temperature distribution enhances system stability, improves product consistency, and ensures long-term equipment reliability.

Metalli Customized Pillow Plate Heat Exchanger Services

Metalli offers highly flexible customization services for pillow plate heat exchangers, tailored to meet your specific requirements. From dimensions and materials to internal channel design, we provide end-to-end support to deliver efficient, application-specific heat transfer solutions. Metalli's experienced engineering team provides technical guidance throughout the entire process. We welcome custom designs based on your drawings and application needs.

Customizable Features

Welding Pattern & Seam Design

Custom spot-welding layouts and seam configurations are optimized for efficient fluid distribution and heat transfer.

Flexible Dimensions

Plate width, length, and thickness can be fully customized to match your system size and integration needs.

Various Shapes & Forms

We support a wide range of formats, including flat plates, curved structures, clamp-on jackets, and other special geometries for niche applications.

Material Options

Select from premium-grade stainless steel, titanium, or other materials to ensure high corrosion resistance and long-term durability.

Key Technical Parameters of Pillow Plate Heat Exchangers

Metalli offers a wide range of configurations and material selections for pillow plate heat exchangers, ensuring reliable performance across demanding thermal management applications. Below are the core technical specifications:

| Feature | Specification |

|---|---|

| Available Materials | A wide selection of stainless steel grades, including 304, 316L, 310S, 430, 2205, 2507, 904L.Other materials such as Titanium, Duplex (SS2205/2507), and LDX-2101 are also available upon request. |

| Compatible Fluids | Suitable for various working media, including chilled water, brine, ethylene glycol, refrigerants, steam, thermal oil, and hot water. |

| Surface Finishing | Options include mechanical polishing, mirror polishing, chemical pickling and passivation, sandblasting, electropolishing, and brushed finish. |

| Certifications | All products are manufactured in accordance with international standards, including ISO 9001, ISO 14001, and ISO 45001. |

Standard Specifications

The table below presents commonly offered dimensions and performance data for Metalli pillow plate heat exchangers. Custom sizes, shapes, and pressure ratings are available on request.

|

Size (L×W×T, mm) |

Material (Stainless Steel) |

Max Temp (°C) |

Max Pressure (MPa) |

Transfer Area (m²/PC) |

Weight (kg/PC) |

| 1500x2500(1.0x2) | 304 | 600 | 2 | 7.5 | 60 |

| 1500x1500 (1.0x2) | 304 | 600 | 2 | 4.5 | 36 |

| 1200x2400(1.0x2 | 304 | 600 | 2 | 5.8 | 46 |

| 600x2000(1.0x2) | 304 | 600 | 2 | 2.4 | 19 |

| 1500x2500(1.0x2) | 316L | 600 | 2 | 7.5 | 60 |

| 1500x1500(1.0x2) | 316L | 600 | 2 | 4.5 | 36 |

| 1200x2400(1.0x2) | 316L | 600 | 2 | 5.8 | 46 |

| 600x2000(1.0x2) | 316L | 600 | 2 | 2.4 | 19 |

| 1200x2400(1.0x2) | 2205 | 600 | 2 | 5.8 | 46 |

| 600x2000(1.0x2) | 2205 | 600 | 2 | 2.4 | 19 |

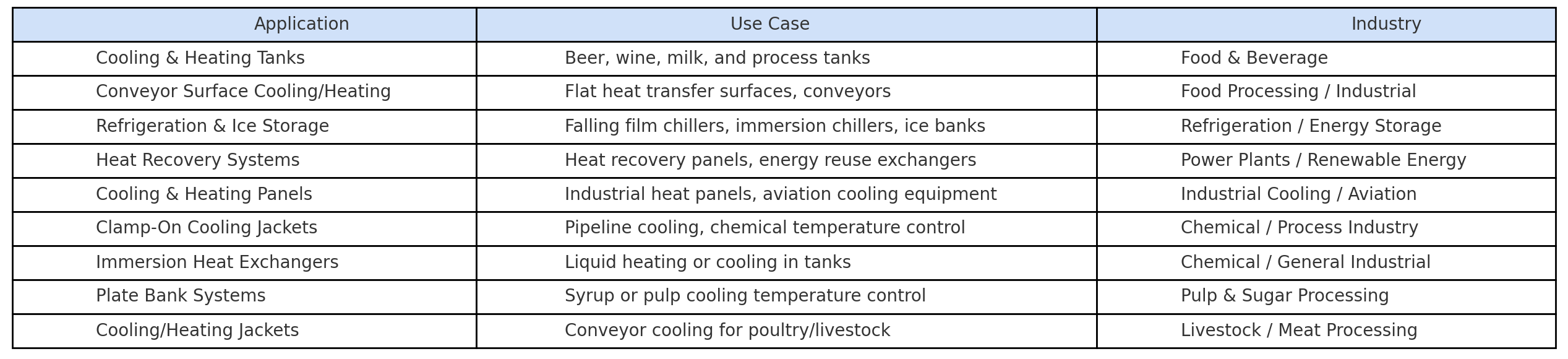

Pillow plate heat exchangers from Metalli are widely used across food, chemical, energy, and industrial sectors. Below is a summary of typical applications and industries we serve.

About Metalli — Experts in Pillow Plate Heat Exchanger Solutions

About Metalli — Experts in Pillow Plate Heat Exchanger Solutions

With over 15 years of experience in precision metal fabrication and aluminum profile development, Metalli has become a trusted provider of advanced thermal management systems. Our pillow plate heat exchangers are engineered to deliver high performance in demanding applications across the energy, industrial, and food processing sectors.

By integrating innovation with strict quality control and flexible customization, we help global clients—particularly in Europe and North America—achieve efficient, durable, and cost-effective thermal solutions tailored to their specific operating conditions.