PRODUCTS

Custom Metal Fabrication Deep Drawn Parts

We have been providing thermal solutions over 15 years for almost every industrial application field covering electronics, power generations, data centers, new energy, automobile, medical, chemical and construction machinery.

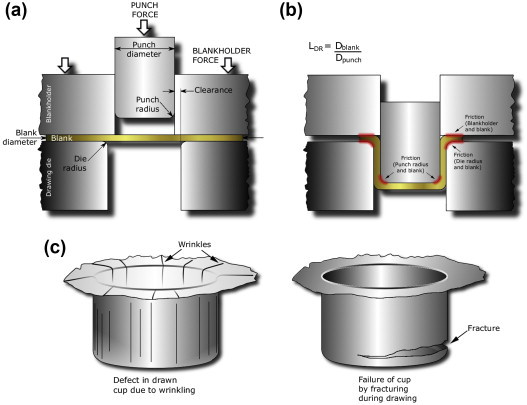

Deep drawing is a sheet metal forming process in which a sheet metal blank is radially drawn into a forming die by the mechanical action of a punch. It is thus a shape transformation process with material retention. The process is considered "deep" drawing when the depth of the drawn part exceeds its diameter. This is achieved by redrawing the part through a series of dies. The flange region (sheet metal in the die shoulder area) experiences a radial drawing stress and a tangential compressive stress due to the material retention property. These compressive stresses (hoop stresses) result in flange wrinkles (wrinkles of the first order). Wrinkles can be prevented by using a blank holder, the function of which is to facilitate controlled material flow into the die radius.

Category:

Deep Drawing

Enter product details or other specific requirements to receive an accurate quote. We will reply within 24 hours.

|

PRODUCT DESCRIPTION |

||

|

NO. |

ITEM |

DESCRIPTION |

|

1 |

Material |

Mild steel, stainless steel, aluminum |

|

2 |

Dimension L*W*H |

Common 0.5mm-1000mm |

|

3 |

Thickness of material |

Common 0.2mm-20 mm |

|

4 |

Process |

Deep drawing |

|

5 |

Tolerance |

+/-0.2mm |

|

6 |

Surface treatment |

Powder coating, galvanization, anodizing |

|

7 |

Application |

Industry |

|

8 |

Warranty time |

1 -2 year(s) |

|

9 |

Place of Region |

Jiangsu province of China |

|

10 |

Samples service |

Available |

▼ Product picture

Metalli’s deep drawing capabilities

● Product dimension up to Length*Width 1200*1000 mm

● Depth or height up to 500 mm

● Wall thickness up to 6 mm

● Tolerance ±0.2 mm or less

● Common shapes covering round, cone, square, rectangle, and irregular

● Tools design available in house

● 10 hydraulic press machines from 100 tons to 1000 tons

Brief of deep drawing

Deep drawing is a sheet metal forming process in which a sheet metal blank is radially drawn into a forming die by the mechanical action of a punch. It is thus a shape transformation process with material retention. The process is considered "deep" drawing when the depth of the drawn part exceeds its diameter. This is achieved by redrawing the part through a series of dies. The flange region (sheet metal in the die shoulder area) experiences a radial drawing stress and a tangential compressive stress due to the material retention property. These compressive stresses (hoop stresses) result in flange wrinkles (wrinkles of the first order). Wrinkles can be prevented by using a blank holder, the function of which is to facilitate controlled material flow into the die radius.

key word: