PRODUCTS

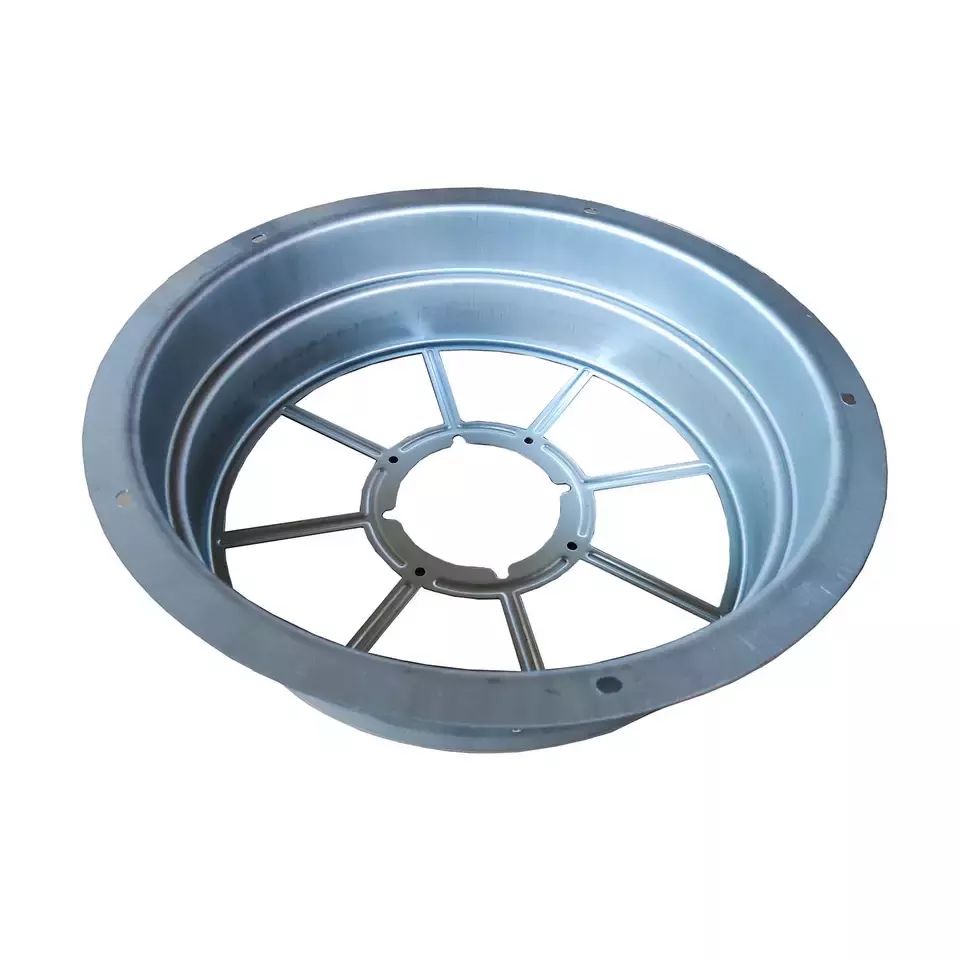

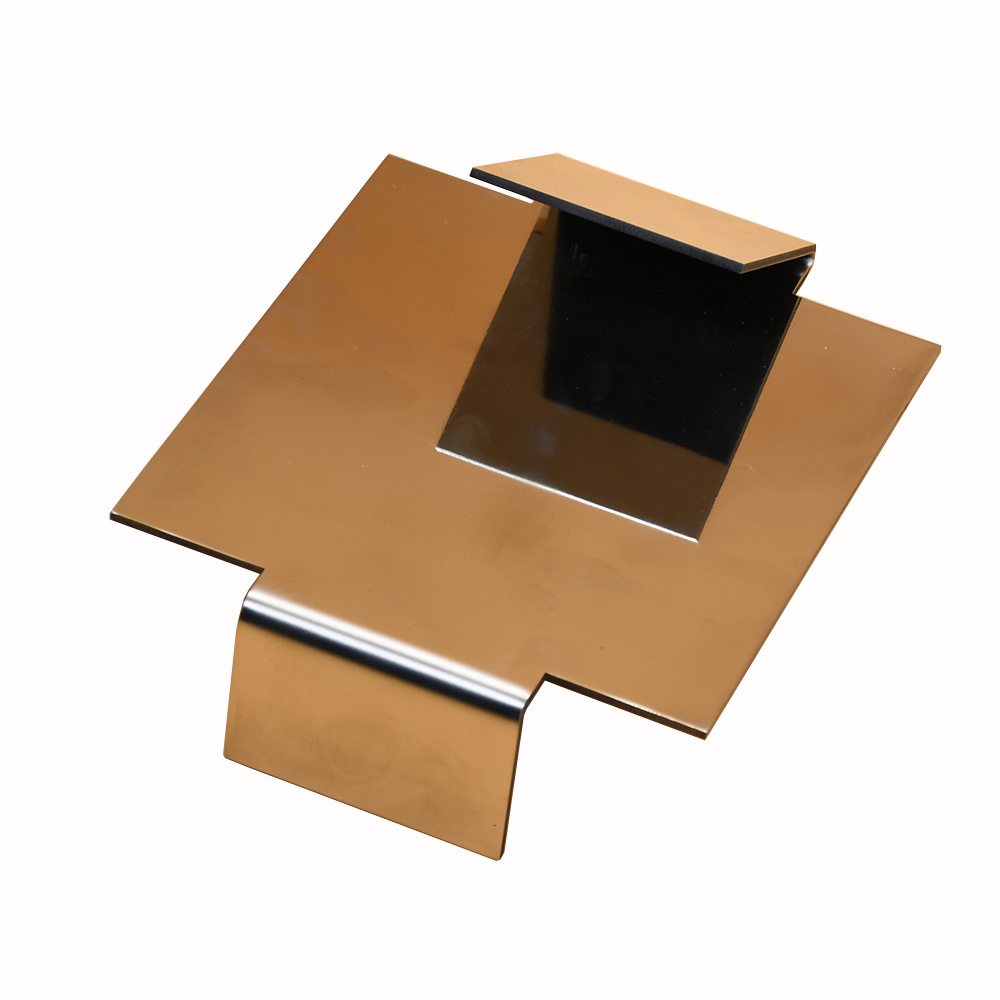

Sheet Metal Fabrication — Custom Precision Metalwork Solutions

From laser cutting to deep drawing, Metalli offers end-to-end fabrication services tailored to your industry needs.

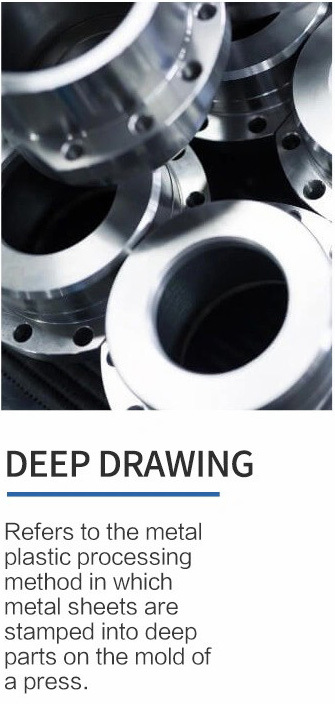

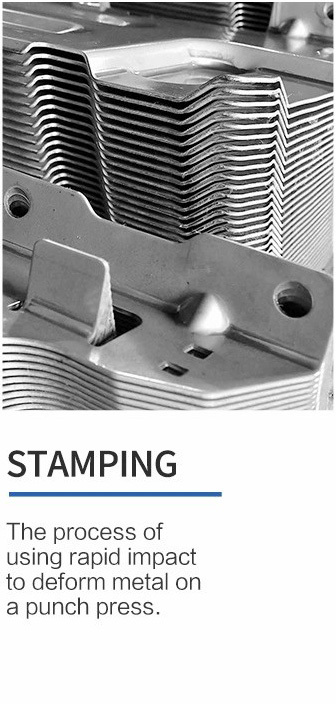

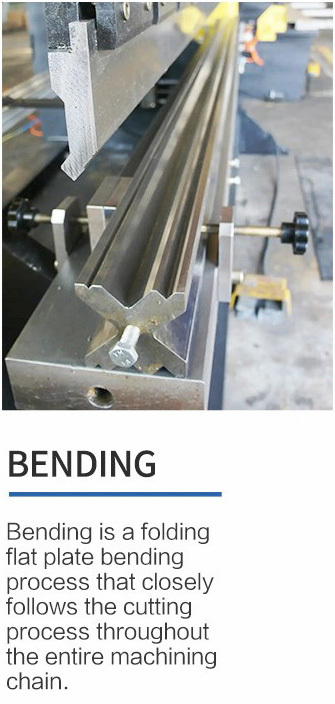

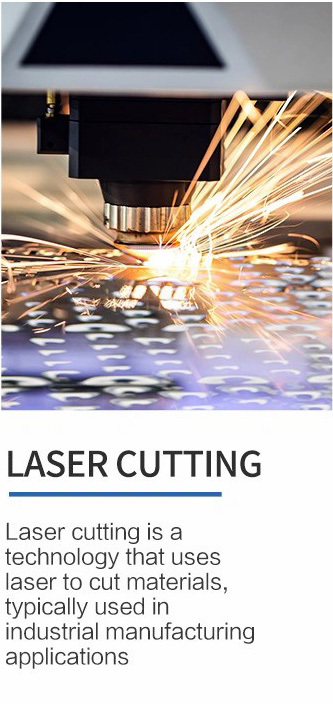

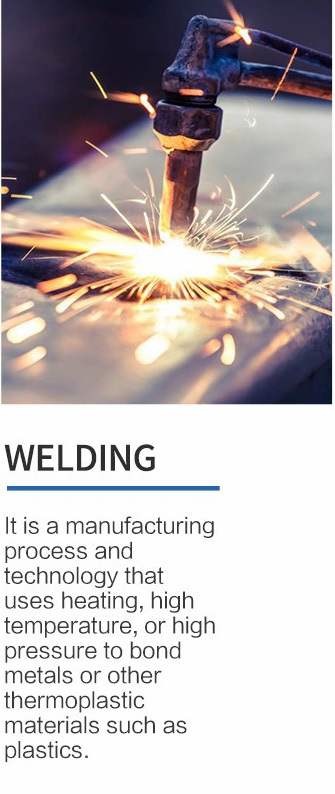

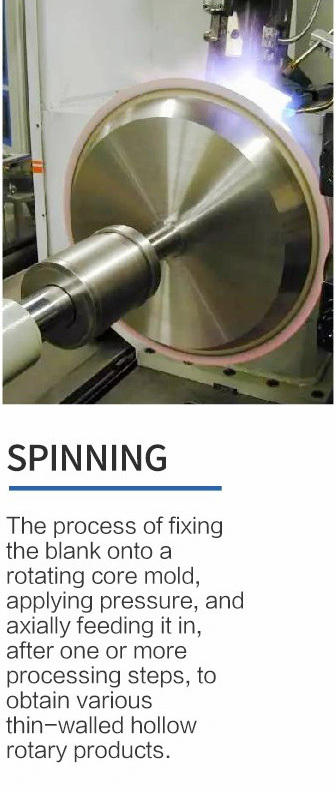

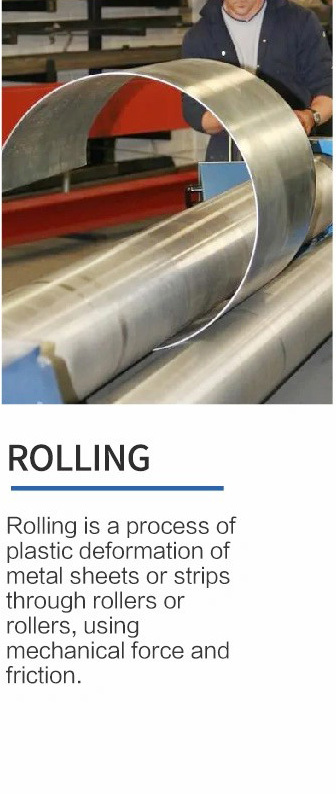

Sheet metal fabrication is a multi-stage process that transforms flat metal sheets into precise, functional components. Depending on the complexity of each project, the workflow may include laser cutting, bending, stamping, welding, surface finishing, and final assembly.

At Metalli, we specialize in full-process sheet metal fabrication, offering a wide range of capabilities including deep drawing, stamping, bending, laser cutting, welding, rolling, metal spinning, and surface treatment. Supported by our in-house engineering expertise, we turn custom designs into reliable, cost-effective, and high-performance solutions for applications in automotive, industrial machinery, electronics, and energy sectors.

Click each process to view detailed capabilities and product categories.

Explore:

Why Metalli?

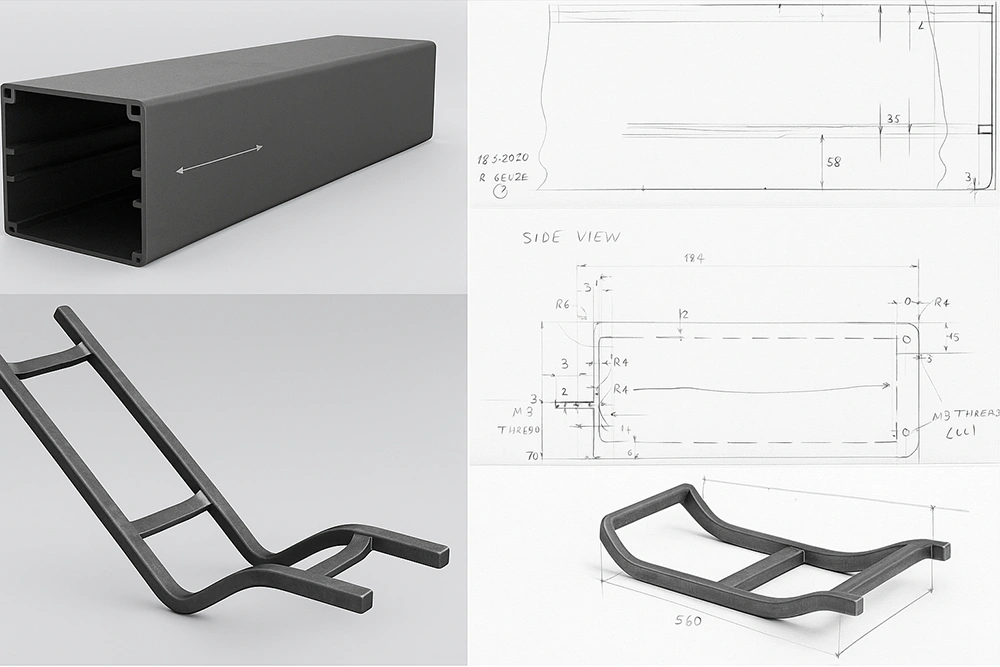

Since 2010, Metalli has been providing precision metal components to global industrial clients. Our product line includes sheet metal parts, custom aluminum profiles, CNC-machined components, and complex assemblies — all tailored to meet specific application needs. With strong engineering support and in-house tooling capabilities, we deliver both standard and fully customized solutions that meet international standards in performance and cost-efficiency.

Custom Metal Fabrication Process

Metalli offers full-service custom fabrication tailored to your drawings, specifications, and application needs. From prototype to mass production, we support your project at every step:

Our Customization Workflow:

Requirement Submission – Send us your drawings, specifications, or design ideas.

Engineering Review – Our technical team evaluates feasibility and proposes solutions.

Quotation & Confirmation – Receive a detailed offer based on materials, process, and quantity.

Tooling & Sample – We design tooling (if needed) and produce samples for approval.

Mass Production & Delivery – Final production begins with strict quality control and on-time shipment.

Ready to Start Your Custom Project?

Send us your requirements and drawings — whether it's a 3D CAD file or a hand-drawn sketch. Our engineering team will evaluate your design and respond within 24 hours with a tailored manufacturing solution that matches your application and budget.

We accept a wide range of file formats, including DXF, STEP, IGS, PDF, and other commonly used CAD formats for sheet metal and CNC machining projects.

If needed, we can also assist in format conversion, 3D modeling, or adjusting your design for optimal manufacturability.

Frequently Asked Questions (FAQ)

1. Do you accept custom metal part orders based on drawings or samples?

Yes. We specialize in custom sheet metal fabrication and accept orders based on 2D/3D drawings or physical samples. Our engineers can also assist in optimizing your design for production.

2. What is your typical lead time for metal fabrication projects?

Lead time varies based on complexity and quantity. For prototypes or small batches, production typically takes 7–15 days. Mass production orders may take 20–30 days. Please contact us for a detailed quote.

3. What materials can you work with?

We work with a wide range of materials including stainless steel, carbon steel, aluminum, copper, and titanium. Material certifications can be provided upon request.

4. What is your minimum order quantity (MOQ)?

We do not enforce a strict MOQ. Small batch orders are welcome, especially for new projects or trial runs. However, unit prices may vary based on quantity.

5. Can you provide surface treatments like powder coating or anodizing?

Yes. We offer various surface treatments including powder coating, painting, polishing, anodizing, sandblasting, and more, depending on the material and end-use requirements.